Machinery and equipment

Global Industrial 3D Printing Market @ CAGR 22% and By Offering (Materials, Printers, Software ,Services), Process (Direct Energy Deposition, Material Extrusion, Power Bed Fusion, Sheet Lamination, Binder Jetting, Material Jetting, Vat Photopolymerization), Technology (Polyjet Printing, Fused Modelling Deposition, Electron Beam Melting, Inkjet Printing, Digital Light Processing, Direct Metal Laser Sintering, Laminated Object Manufacturing), Application (Manufacturing, Prototyping, High Voltage), Industry (Healthcare, Consumer Goods, Automotive, Printed Electronics, Food and Culinary, Aerospace & Defence, Oil & Gas), Region (Asia-Pacific, North America, Europe, ROW)

Global Industrial 3D Printing Market: Press Release

The Global Industrial 3D Printing Market was valued at USD 2.8 Billion in 2023 and is estimated to reach USD 19.2 Billion by 2033, growing at a CAGR of 22 % from 2024 to 2033.

Scope of the market:

Industrial 3D printing or additive manufacturing (AM) is a manufacturing method for creating a physical product from a computer-aided design digital file. The process of opposite of traditional or subtractive manufacturing, where a product is cut from material. A wide range of industrial or consumer printers uses diverse materials plastics, metals, and alloys being most the popular to produce prototype and final parts. The benefits of Industrial 3D printing are reduced waste, low-cost complexity, reduced lead time, repair parts in the field, and Eliminate tooling. Metal additive manufacturing develops with improvement in speed and precision. High initial investment costs, limited material options, and performance, post-processing, and finishing requirements are some of the factors that may hamper the industrial 3D printing market in the forecast period. As technology continues to advance and adoption increases, the potential for expansion and growth in the market is significant. Furthermore, additive manufacturing offers opportunities for sustainability and material efficiency by reducing waste and energy consumption as compared to traditional manufacturing methods.

For LinkedIn:

https://www.linkedin.com/pulse/top-10-companies-global-industrial-3d-mlv6e

Economic Impact of Covid-19:

The pandemic highlighted the importance of personalized healthcare solutions, medical implants, and devices. Industrial 3D printing enabled the customization and production of these solutions, as it was an urgent need for devices such as PPE Kits, and testing kits ventilators. Researchers and companies have been continuously developing new application, materials, and processes. These factors have shown a positive impact on the industrial 3D printing market.

The analysis of the COVID-19 recovery trajectory provides an overview of the main strategies that industries are implementing to respond to and recover from the economic crisis. It also focuses on the post-pandemic and pre-pandemic era of the Global Industrial 3D PrintingMarket through PEST analysis, SWOT, Quantitative and Qualitative analysis, Attractive analysis, and DROs. Innovations by market players and an increasing number of products will propel the growth of this market.

Key Players:

- Stratasys (US)

- 3D Systems (US)

- Materialise (Belgium)*

- EOS (Germany)

- Ultimaker (Netherlands)

- XYZprinting (Taiwan)

- Formslabs (US)

- Hoganas (Sweden)

- TRUMPF (Germany)

- CleenGreen 3D (Ireland)

- HP (US)

- Groupe Gorge (France)

- One Click Metal (Germany)

- Spectroplast (Switzerland)

- DSM (Netherlands)

- Sisma SpA (Italy)

- Others

The above key players in the Global Industrial 3D Printing Market can be changed according to the client’s requirements.

Moreover, the key players aim towards expansion, joint ventures, collaboration, mergers, and acquisitions to advance capabilities in the Industrial 3D Printing Market.

Recent Developments in Global Industrial 3D PrintingMarket.

In 2023:

- Merit3D reports record orders of over a million 3D printed parts.

Merit3D has received funding as part of the 10 million USD Utah Manufacturing Modernization Grant, which has enabled it to deliver what it believes could be the largest order of 3D printed parts ever. Adhesive Technologies has placed an order of over 1 million parts, to be delivered at 40,000 pieces per week.

- Align Technology, the manufacturers of Invisalign clear aligners have announced an agreement to acquire polymer 3D printing from Cubicure GmbH for 79 million Euros. The medical device firm believes this acquisition will strengthen its existing intellectual property in direct 3D printing in applications.

- EOS North America introduces AM Turnkey to remove industrial 3D printing roadblocks.

- HP launches new 3D printing automation solutions at RAPID + TCT and announces 3 new DMPs. This is the new automation solutions, as well as expanded materials, software, and services to help customers scale 3D printing parts production.

Global Industrial 3D PrintingMarket Key Benefits:

- The report provides information regarding key drivers, restraints, and opportunities with impact analysis.

- Quantitative and Qualitative analysis of the current market.

- Estimations for the forecast period 2032.

- Historical data and forecast data.

- Recent developments and trends in the market.

- Market share of the market players, company profiles, SWOT analysis, and competitive landscape.

- Covid-19 Impact analysis

Global Industrial 3D PrintingMarket Segmentation:

By Offerings:

- Materials

- Printers

- Software

- Services

By Process:

- Direct Energy Deposition

- Material Extrusion

- Power Bed Fusion

- Sheet Lamination

- Binder Jetting

- Material Jetting

- Vat Photopolymerization

By Technology:

- Polyjet Printing

- Fused Modelling Deposition

- Electron Beam Melting

- Inkjet Printing

- Digital Light Processing

- Direct Metal Laser Sintering

- Laminated Object Manufacturing

By Application:

- Manufacturing

- Prototyping

- High Voltage

By Industry:

- Healthcare

- Consumer Goods

- Automotive

- Printed Electronics

- Food and Culinary

- Aerospace & Defence

- Oil & Gas

Based on Region:

Asia-Pacific

- Japan

- China

- India

- Australia

- New Zealand

- Rest of Asia-Pacific

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- Italy

- Spain

- UK

- Rest of Europe

The rest of the World

Each of the market segments has been analyzed in detail for market trends, recent trends and developments, drivers, restraints, opportunities, and competitive analysis.

Research Scope:

|

Report Scope |

Details |

|

Base Year |

2023 |

|

Historical Years |

2019 to 2022 |

|

Forecast Years |

2024 to 2033 |

|

Market Size 2023 |

USD2.8 BN |

|

Market Revenue 2033 |

USD 19.2 BN |

|

Growth Rate 2024- 2033 |

22% |

|

Report Coverage |

Trends, SWOT Analysis, Competitive Landscape, DROs, Revenue Forecast, PEST Analysis. |

|

Segments Covered |

Offering, Process, Technology, Application, Industry, Region |

|

Companies Mentioned |

Stratasys (US), 3D Systems (US), Materialise (Belgium), EOS (Germany), Ultimaker (Netherlands), XYZprinting (Taiwan), Formslabs (US), Hoganas (Sweden), TRUMPF (Germany), CleenGreen 3D (Ireland), HP (US), Groupe Gorge (France), One Click Metal (Germany), Spectroplast (Switzerland), DSM (Netherlands), Sisma SpA (Italy) |

|

Customization |

Yes |

Regional Analysis:

North American Industrial 3D printing market size reached USD 7.2 Billion in 2023 and is expected to grow with a CAGR of 22% by the end of 2031. TheIndustrial 3D Printing Market in North America is growing steadily and is driven by adoption across different industries such as healthcare, consumer goods, and automotive. The industry has continuously witnessed growth due to its technological advancements, and improvement in 3D printing speed, precision, and material options. The presence of key players such as Stratasys Ltd., 3D Systems Corporation, EOS GmbH, and HP are offering a wide range of applications in 3D printing technologies and solutions. Furthermore, the future of Industrial 3D Printing looks promising due to factors like expanding applications and increasing investments by giant players and government, whichfurther accelerates across a wide range of industries. Moreover, North America is ripe with opportunities for collaboration, and investments and gives the potential for additive manufacturing across a wide range of applications and industries. North America also focuses on expanding the range of materials thatare suitable for industrial 3D Printing and also offers diverse opportunities in healthcare industries.

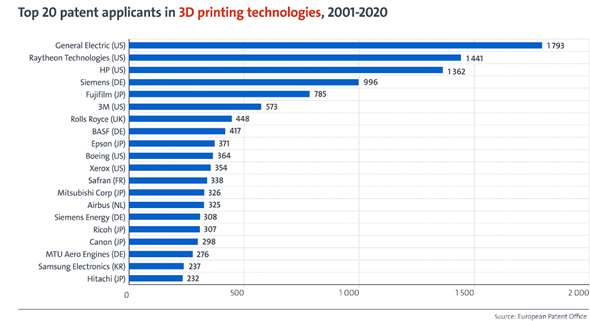

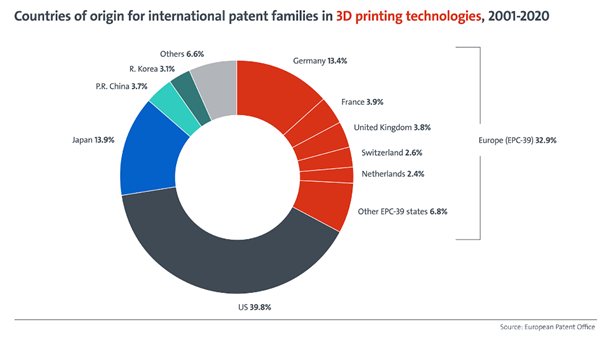

According to European patent Office:

The European market is increasing as it has a strong ecosystem of research, institutions, and industry collaboration which is focused on advanced 3D printing technology. Regulatory bodies are also working to establish guidelines for using 3D printing in various industries such as aerospace and healthcare. Moreover, the customization capacities of 3D printing are driving its adoption in healthcare for patients implants, surgical guides, prosthetics, and medical devices are presenting significant opportunities for the industrial 3D printing market in the European region. Additionally, it offers opportunities to achieve goals by enabling lightweight components and optimizing energy consumption. In Europe, Germany has emerged as the clear leader with 41 %of Europe's share followed by France with 12%.

A report published by the European Patent Office (EPO) today shows that innovation in additive manufacturing, also known as 3D printing, has surged in the past decade. The study, Innovation trends in Additive Manufacturing, finds that between 2013 and 2020, international patent families in 3D printing technologies grew at an average annual rate of 26.3% – nearly eight times faster than for all technology fields combined in the same period (3.3%).

According to European patent Office:

Key questions answered by this report.

- Top market players contributing to the revenue?

- Trending strategies by the players?

- Which region will be the leading one in the forecast period?

- Factors that drive the Global Industrial 3D PrintingMarket?

- Which factors will affect the Global Industrial 3D Printing Market?

- How Covid-19 pandemic impacted the growth of the Global Industrial 3D PrintingMarket?

- Which Segment accounted for the Global Industrial 3D PrintingMarket shares?

Interested in this report?

Global Industrial 3D Printing Market from 2024 to 2033.

TOC